These Smart Sensors Improve Resiliency and Alert Residents, Responders to Danger More Quickly

Stevens researcher explores distributed sensing to help buildings, bridges, tunnels and roads signal when they're stressed

Buildings and bridges weakened by age, fire or weather can't tell us when they're ailing.

But maybe soon they will, thanks in part to new Stevens Institute of Technology research.

Stevens engineering professor Yi Bao is working hard on the challenge, developing an innovative new method of threading and embedding thin, light-powered sensors in building materials that take their pulse continuously, enabling quick analysis and action before disaster strikes.

"Currently, most buildings do not have sensors beyond simple light, motion and smoke sensors," explains Bao. "High-rise buildings and long-span bridges might also have sensors to monitor vibration.”

"But that's not sufficient, in our opinion. You need to understand all the degradation mechanisms of the structure, under mechanical and thermal loadings, at all moments."

High-tech materials, reporting back in real time

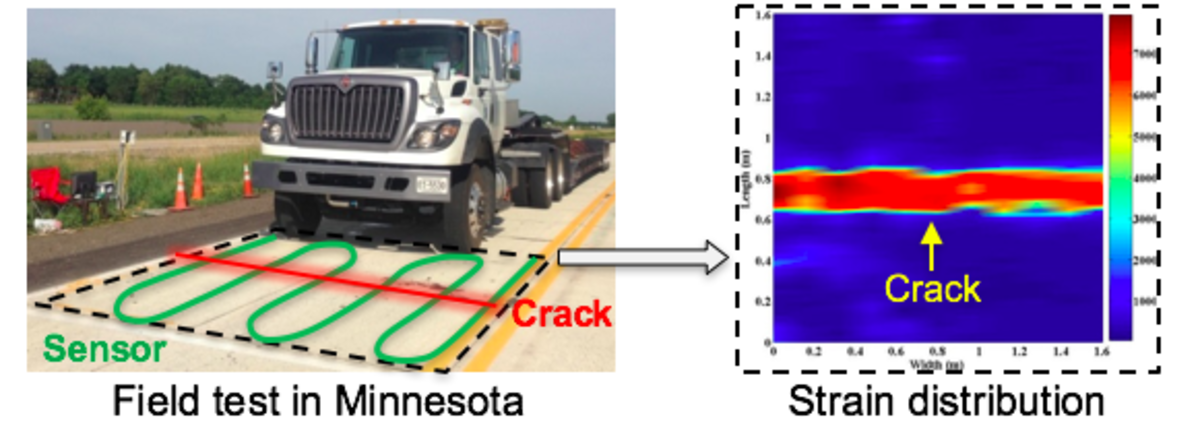

To help design these new, safer buildings and bridges, Bao's team is developing and testing a new technology known as distributed fiber optic sensing that can be embedded in concrete, wound around steel bars, attached to wood or strung along other hard surfaces.

The sensors are composed of multi-layer, telecommunication-grade optical fibers manufactured with high-purity silica cores and cladding that can efficiently reflect light internally for distances of up to 100 miles.

"These are not like current sensors, which can only measure data at a single point wherever a sensor is installed," Bao points out. "A network of these distributed sensors is more like the human nervous system: continuously measuring the condition of the structure at every point and reporting trouble spots immediately."

That's critical, because even a single crack deep within a structure can affect its surrounding stress field. So it's important to know what's happening everywhere, every moment.

"That one change, that small crack deep inside that can potentially become bigger quickly, can be captured by our new sensors in ways we couldn't before," he notes.

Bao's sensors measure and report key variables including material temperature, load, strength and deformation — in essence, the forces acting along all the continuous points in a structure or piece of infrastructure such as pavement.

A data acquisition box collects all the data and uploads it wirelessly to cloud servers in real time. Bao's team is working to develop additional algorithmic systems that would quickly analyze the data stream under normal and extreme temperatures and loads, taking some of the human guesswork out of the process and (for example) sending alerts when corrosion in steel bars appears likely to be occurring.

"This is very useful in an emergency when you need to determine, for example, whether people can re-enter a building that has been damaged by fire or earthquake to do search and rescue," Bao notes. "It could help save lives, and help protect the safety of first responders."

The U.S. government's National Institute of Standards and Technology (NIST) was impressed enough with the concept to fund research of Bao's toward the development of distributed sensing technologies that can sense and report potential fires.

And a Minnesota field test demonstrated another application of Bao's work: how sensors woven into the concrete in roadways or bridges can help spot early-stage cracking and other weaknesses during periods of cold weather.

A vision of smarter buildings, cities, infrastructure

It's a good time for Stevens to ramp up its sensing research: engineers nationwide are also beginning to experiment with new sensing technologies, for example in the reconstruction and upgrade of the Canarsie Tunnel connecting Brooklyn and Manhattan beneath the East River.

"That tunnel was flooded during Hurricane Sandy with corrosive salt water," explains Bao. "Now, as the tunnel is repaired, they would like to use distributed fiber optic sensing to monitor its condition continuously. If it is leaking, for instance, sensors could potentially detect the situation early, in time to fix it, rather than waiting for someone to notice visually. We are watching all this very closely and stand ready to assist or participate if needed."

The proposed Stevens system could also be used for long-term monitoring of buildings, such as when municipal officials, property owners and other stakeholders are working to determine whether a given structure (or even a section of a building) remains suitable for renovation or not.

"Buildings are expensive," Bao points out. "In some cases, you will need to demolish and rebuild, but in other cases the section or structure may be strong enough to repair and continue to use. Usually we are making educated guesses about these things, without complete data sets on stress fields throughout the entire structure, because we cannot physically go inside the concrete in the middle.”

"Our system, if it works, could make a huge difference in this decision-making process."

It's all part of Bao's ultimate goal of designing more intelligent infrastructure.

"The long-term vision is to develop smarter structures that transform planning and performance,” he concludes. "These new smart structures of the future will be developed through innovations in sensors, materials and design.

"Our team is already working on smarter materials, and novel types of sensors will also be critical for the safety and management of smart infrastructure."