A Catalyst for Change: Stevens Seniors Develop Process That Could Simplify Biodiesel Production

Petroleum-based diesel adds millions of metric tons of CO2 into the atmosphere each year, fueling climate change. For their senior design project, Stevens students are developing a biodiesel solution that could make an impact

Fuel permeates our lives. Every day, we rely on our networks of roads, railways, maritime routes, and skyways to get the supplies that make our lives easier and propel the global economy. But the by-products of burning diesel fuels to power vessels through these networks also permeate our atmosphere. Petroleum-based diesel adds pollutants such as carbon monoxide, sulfur dioxide, and hydrocarbons to our atmosphere and oceans. With the threat of climate change quite literally “fueled” by these pollutants, a team of Stevens students headed to their lab to problem-solve.

In the U.S., the transportation sector emitted 461 million metric tons of carbon dioxide (CO2) in 2018, according to the U.S. Energy Information Administration (EIA). NASA reports that the climbing concentration of CO2, a greenhouse gas, in the atmosphere since the Industrial Revolution is “the most important long-lived ‘force’ of climate change.”

The Stevens team—Ashley Reyes, Victoria A. Stabile, Nicole M. Strezewski, and Chelsea Yagel—hopes to help mitigate climate change challenges through an innovative approach to biodiesel fuel production.

Specifically, their team is demonstrating that solid catalysts can be incorporated into biodiesel production and recycled after the process. Their research could potentially simplify biodiesel production processes, helping to improve the costs and yield of biodiesel fuel.

As chemical engineering students, the team has learned skills to design, operate, and improve various chemical processes that are vital to society. As part of their senior design project, they aim to put those skills into action.

“I’ve always been interested in the environment and applying chemical engineering skills to create environmentally friendly solutions,” said Stabile. “This project was a perfect application of that.”

“A great moment for all of us”

Biodiesel is considered a carbon-neutral fuel that may have significant environmental benefits. Feedstocks for producing biodiesel include soy and other vegetable oils, animal fats, and green algae. While biodiesel does release the greenhouse gas CO2 into the atmosphere, it is considered more environmentally friendly than petroleum-based fuels. The reason is that the plant feedstock used to produce biodiesel absorbs CO2 during plant growth, offsetting the CO2 emissions from burning biodiesel fuel. According to the U.S. Department of Energy, B100, a form of biodiesel, can reduce CO2 emissions by 74% when compared with petroleum diesel.

“Carbon neutral fuels, such as biodiesel, are necessary to reduce the amount of CO2 in the atmosphere,” said Yagel. However, the use of liquid catalyst in current industrial processes add to the expense of producing biofuels. Yagel explained that the chemical process to produce biodiesel involves separating and neutralizing liquid, a very energy-intensive process.

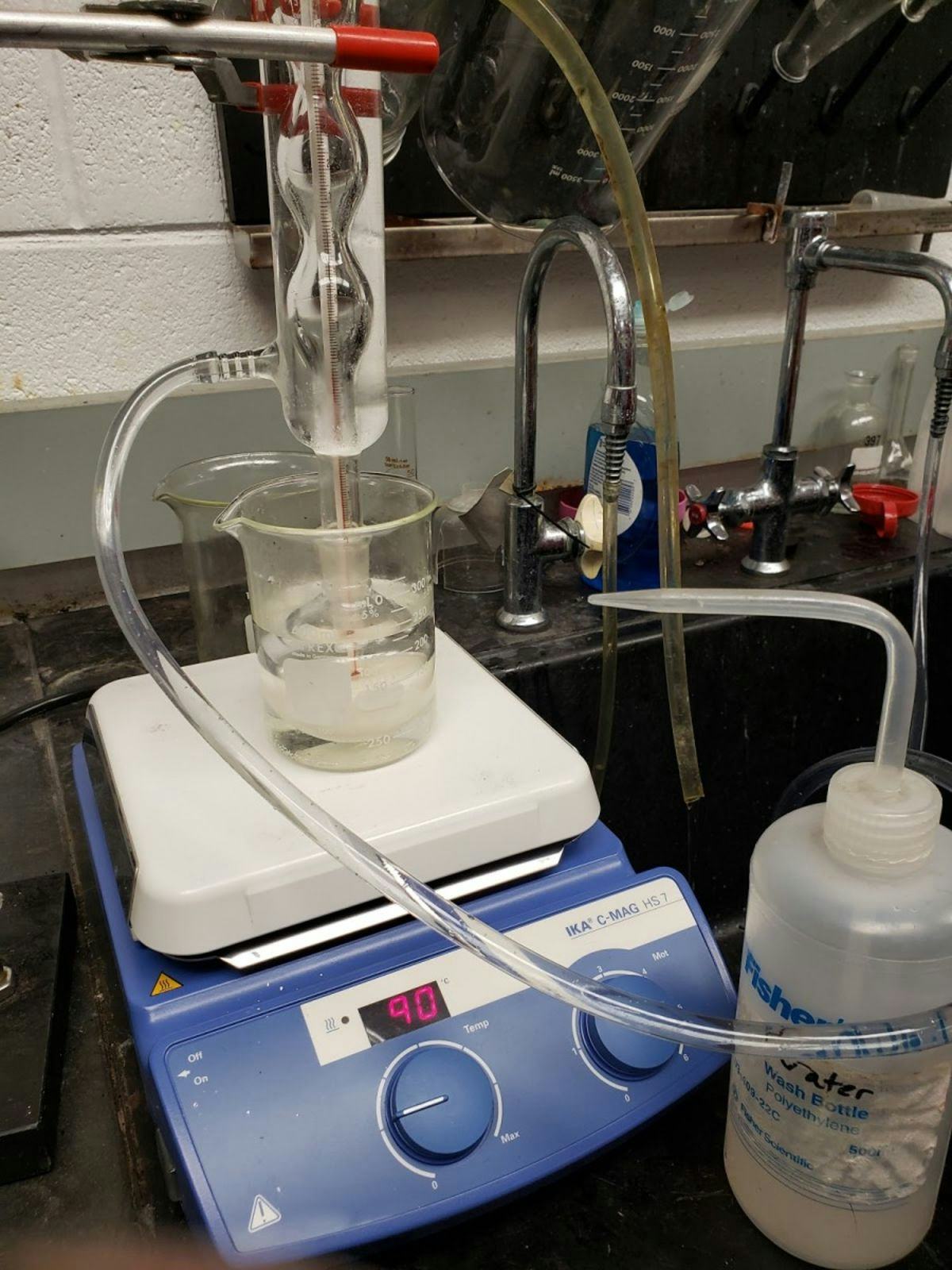

In comparison, their process filters a solid catalyst from a liquid, a simpler process. The team first had to create a solid calcium oxide catalyst; this involved the use of a high-temperature furnace. Tests and experiments took place in different conditions and laboratories located in McLean Hall, the home of Stevens Institute of Technology’s Department of Chemical Engineering and Materials Science. Ultimately, they successfully catalyzed the reaction to produce biodiesel.

The team was excited to see that they accomplished what they set out to do. “Seeing our own catalyst in action was a great moment for all of us,” said Stabile.

Their simplified approach eliminates the need for expensive liquid separation methods, resulting in a cleaner product and reduced biodiesel production costs. Another benefit of their process is the ability to filter and reuse the catalyst they created in the lab, minimizing waste and limiting the need for using new resources.

Implementing their process on a large scale could make biodiesel production cheaper and more industrially feasible. The team is already at work determining the scalability and economics of the process outside of the lab and developing a model using Aspen Plus, a chemical process simulator.

Real-world experiences: A bridge to the next phase of their lives

The senior design project is the culmination of a Stevens education focused on problem-solving, multi-disciplinary thinking, and teamwork. Inside and outside the lab throughout this project, each team member demonstrated their strengths in solving problems and accomplishing their objectives.

As graduation nears, these students are thinking about what’s next in their careers.

Yagel is looking to land a job in the pharmaceutical industry. So is Reyes, who would also like to return to Stevens to complete a master’s degree in pharmaceutical manufacturing. Similarly, Strezewski seeks to work toward a master’s degree in project management at Stevens, while working full-time.

As for Stabile, she will begin her job with Merck in vaccine process development, but she also expects to complete a Stevens’ master’s degree in environmental engineering. With so many of them looking to return to Stevens for their graduate degrees, they may even get the chance to meet again, face-to-face, at Stevens’ campus in Hoboken just minutes from downtown Manhattan—hopefully, in the not-so-distant future.

The team appreciates that they had the chance to test out current biofuels research in a lab setting on campus just before the COVID-19 outbreak.

"Often, chemical engineering projects are very simulation heavy, and we wanted to make sure we could produce something tangible," said Sabile.

Still, the simulation component is critically important, too, to show the potential commercial benefits of their process in the future.

"If our process can be implemented on a large scale, it could drastically change our fuel source for cars and vehicles in a much greener way," said Yagel.

Learn more about chemical engineering at Stevens: