Mobility-Assistance System Will Soon be Tested by Stroke Patients at the Kessler Foundation

"When I was young, I had plantar fasciitis and Achilles tendinitis," says Stevens Institute of Technology senior Roger Kleinmann. "I needed to walk with a cane for a while, and was even restricted to a wheelchair at times."

Kleinmann regained his mobility, but never forgot the experience. And when he got to Stevens he decided to go into mechanical engineering so he could use that experience to help others: "When I saw professor Damiano Zanotto’s work, I sought him out and joined his research."

Zanotto, a professor in the Department of Mechanical Engineering, studies wearable technologies to aid people with movement disorders.

"All the projects we do in the Wearable Robotic Systems Laboratory are based on solving existing problems within rehabilitation," says Kleinmann.

The project he was most interested in, and helped bring to fruition, is a robotic ankle-foot orthosis to help stroke patients recover mobility.

A Push In The Right Direction

Nearly 800,000 people in the United States suffer a stroke every year, according to the National Institutes of Health. After a stroke, signals between the brain and muscles are often damaged, which causes difficulty in movement—particularly with walking. "The patient cannot sufficiently lift their foot or project enough force to walk," Kleinmann explains.

Patients can regain mobility through a rehabilitation process known as high-intensity gait training, but it’s long, arduous and often inaccessible. In rehab, a patient is "either hooked up to a large machine that corrects their walking patterns," Kleinmann explains, "or they use traditional treadmill training, which involves a team of physiotherapists physically guiding patient's legs through walk cycles."

But a new idea known as 'rehabilitation robotics' is emerging—and using robots to reduce the physical burden on therapists, and the number of therapists involved in each session. This is because, "the device does the majority of the physical work that therapists are doing," Zanotto says.

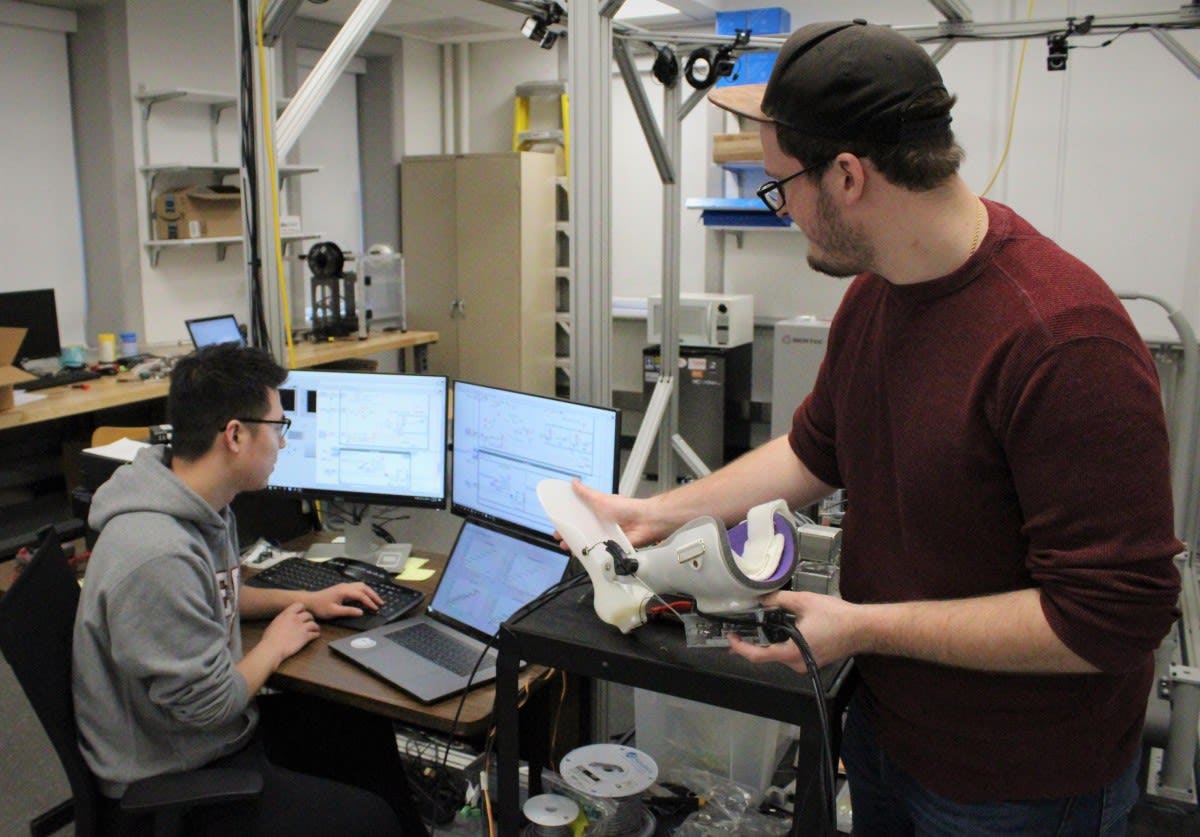

In order to reduce that burden, Zanotto and his students created a robotic orthosis worn over the foot and calf. Then they added motorized components to a commercially available frame and shifted the motor, power sources and other heavy parts to a remote platform that will eventually sit in a backpack worn by the patient, making the device lighter and easier to use.

The conceptual design of that orthosis—as well as the electronics and control systems within it—were created by Zanotto and Yufeng Zhang M.Eng. '16, who was his first Ph.D. student.

Zhang also has personal experience with mobility issues.

"I tore a ligament in my ankle," Zhang says. "I know how bad that feels and how hard it is for people to rehab on their own."

Instantaneous Feedback

The new orthosis uses a variety of sensors to provide real-time feedback to the patient.

Cables routed to the heel and midfoot move due to input from sensors that read the angle of the ankle. The controller checks where the patient’s next step should be, compared with the healthy foot, and if sensors detect the person isn’t stepping with enough force, the device gently 'pushes' the walker in the correct direction.

It all works thanks to Zhang's control system, which receives real-time data from the sensors and tells the motor what to do next.

The device gives "vibro-tactile feedback to help patients adjust movement in real-time," Zanotto adds. "We hypothesize that this strategy will help patients recover a more natural and symmetric gait pattern and correct movement. After multiple therapy sessions, patients [should be able to] walk with a better gait pattern without [even] needing the device."

"No one has ever done this kind of design."

"Most robotic ankle-foot orthotics have two actuators," explains Zanotto, "making them super-heavy, uncomfortable and difficult for the patient to use. We wanted to make a lightweight, affordable device using only one motor."

"No one has ever done this kind of design."

New designs present challenges, and using a single motor was a tricky one to overcome. But Kleinmann created a two-part solution. The first phase involved using motorcycle cables to provide assistive torques to the ankles. The second part involved math.

"We have a motor that actuates both dorsiflexion [lifting off of the ground] and plantarflexion [pushing into the ground]," Kleinman explains. "Motors are heavy and expensive, so we decided to try a semi-active system." That meant countering the plantar flexion with a spring.

Learning Through Doing

Right now, the system is a prototype—but it's attracting wider attention.

Zanotto recently received a grant from the New Jersey Health Foundation to continue developing the orthosis, and he also collaborates with the Kessler Foundation. This summer, the device will be tested on stroke patients at Kessler Institute for Rehabilitation, a top-tier rehabilitation hospital in the nation.

"We are excited about this opportunity and eager to improve the device based on this feedback," says Zanotto.

Ultimately, they’d like to make the device more user-friendly to consumers.

"I hope this device can be commercialized," says Zhang, "and that people can benefit from it."

Kleinmann graduates this summer. While he’s currently designing medical devices for a startup company in Hoboken, he’s also looking for a career after graduation.

He hopes to continue helping others—and he’s grateful for the experiences Stevens gave him to be able to do that. "I trained on many of the machines in the Carnegie lab," Kleinmann says, "and I learned a lot about producing engineering drawings through working with the machinists. I even set up the 3D printer for the lab, since I’ve been using them regularly for six years."

"I really appreciate Roger’s help," Zhang says. "Without him, the project could never have been done in our tight timeframe."

"I stepped out of my comfort zone with this project, but I’m glad I did. Learning in class is valuable, obviously, but I find it best to learn through doing."