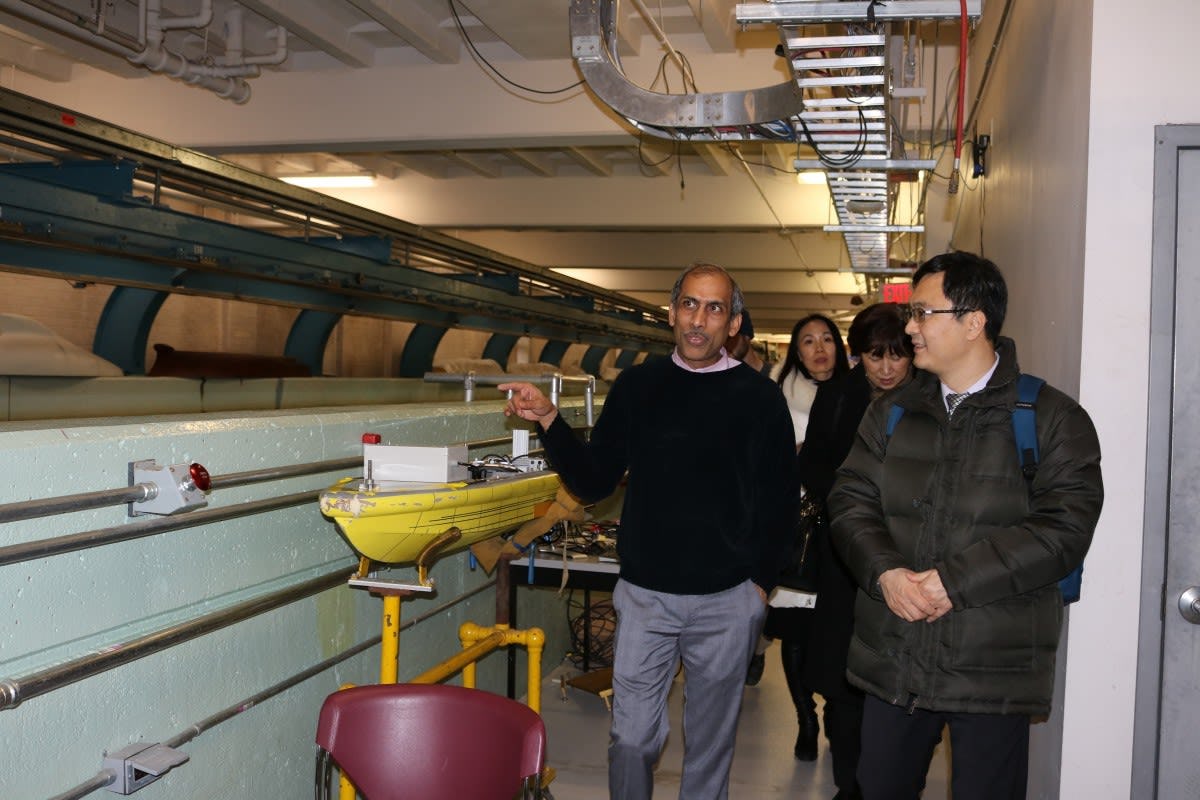

Located in the Davidson Laboratory's primary research facility, our unique high-speed towing tank is 320 feet long, 16 feet wide, and can support a variable water depth of up to 8 feet. It is one of the highest speed towing tanks in the world with a monorail supported, cable-driven carriage capable of speeds of up to 100 feet per second with speed control of .01 feet per second.

Wave-Making Capabilities

The tank contains an articulated, double-flap, programmable wave maker capable of generating monochromatic and random wave fields, as well as several types of wave spectra. This wave maker generates both regular waves and pseudorandom waves and can be programmed to produce nontraditional wave forms such as wave pulses, complex periodic waves and dual and triple wave trains. The wave maker can be used to generate both regular and irregular waves with heights up to 18 inches.

Shallow Water Simulation

Shallow water conditions can be simulated in the tank with the installation of an adjustable slope false bottom. The tank’s improved instrumentation, glass walls for viewing and photography, and public access improvements further enhance the Laboratory’s contributions to fundamental and applied research in ship design, hydrodynamics and ocean engineering. Plunging surf can be produced on a 40 foot surf beach.

Computer programs adjacent to the tank facilities provide menu-driven selection of the following types of wave spectra:

ITTC, ISSC, Pierson-Moskowitz, Bretschneider

JONSWAP

Neumann

Noznesenski-Netsvetayez (Russian)

The laboratory’s simulation software suite is made up of a combination of commercial and in-house modeling codes, several mesh generation tools, and advanced flow visualization tools.

Past and on-going projects encompassing numerical simulation-based research include analysis related to supercavitation, vortex induced vibrations, extreme wave loads on off-shore structures, hydrodynamic and hydroacoustic signatures of submerged bodies and wake hydrodynamics, and aero-hydromechanics of high performance racing yachts. The later activities involved design analysis support for the America’s Cup and Volvo Ocean Race teams and boat designers.

Contact: Dr. Raju Datla ([email protected])