MicroDevice Laboratory

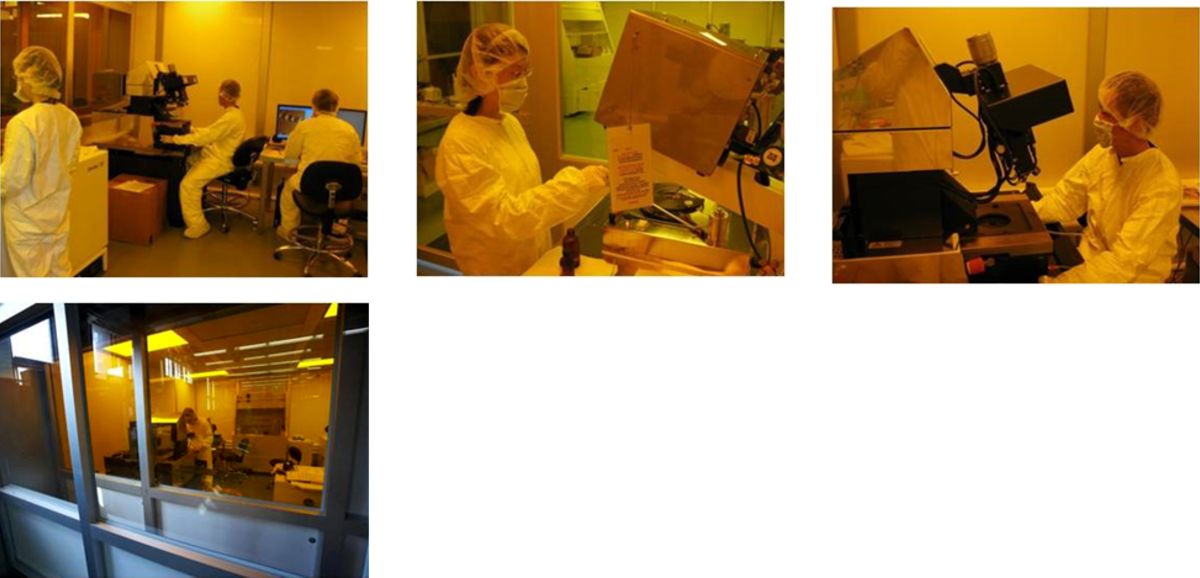

The multi-user MicroDevice Laboratory (MDL) is housed within an 800 square feet cleanroom at Stevens Institute of Technology.

Mission

The MicroDevice Laboratory (MDL) is an Institute multiuser facility whose mission is to provide cutting edge nanofabrication and characterization facilities to support the research and educational programs of then Institute. It furthermore provides hands-on research opportunities for undergraduate and graduate students.

Lab Director

Lab Staff

Dr. Kyungnam Kang (2013-current)

Postdoctoral Scholar

Ph.D. from Louisiana State University

Research: 2D materials

MicroDevice Lab Capabilities

Lithography

Mask aligner, Spin coater, Nanoimprintor, Bake ovens, Wet bench, Microscope

Device Testing

Probe station, SEM, Microscope

Etch & Deposition

DRIE, ICP, XeF2 etcher, Wet etch bench, PVD, Thermal evaporator, MVD

Facility Overview

The multi-user MicroDevice Laboratory (MDL) is housed within an 800 square feet clean room at Stevens Institute of Technology.

Equipment

The following pieces of equipment will be available within the facility:

A complete lithography system including Mask Aligner (Karl Suss MA6), Nanoimprintor (Nanonex), Spin Coater/Drier (Headway Research), Solvent Bench (Clean Air Products), Wet Etch Bench (Clean Air Products), Laminar Hood, Hotplate System (Alpha Multiservices), Ovens (Alpha Multiservices), and Surface treatment (O2 plasma) are available.

For characterization, Environmental Scanning Electron Microscope (SEM, FEI) is also available.

For deposition, Physical Vapor Deposition (PVD, Denton Vacuum), Thermal Evaporator (Ladd Research), Sputter Coater (Pelco), and Molecular Vapor Deposition (Applied MST) are installed. In addition, Deep Reactive Ion Etcher (DRIE, BMRTek), XeF2 Etcher (Xactix), and Inductively Coupled Plasma Etcher (ICP, BMRTek) are available along with other testing equipment such as Microscope (Nikon) and Probe Station (Signatone).

Lithography

Hot plate

Convection oven: Barnstead Lab-Line class 100 clean room oven

Spin coater: Headway Research PWM32-PS-R790

Mask aligner: Karl Suss Microtec MA6/BA6

Wet bench: Clean Air Products

Nanoimprintor: Nanonex NX-1000

Wet Etching

Wet bench: Clean Air Products

Dry Etching

XeF2 etcher: XACTIX Xetch e1

Deep reactive ion etcher (DRIE): BMR Technology DSE200

Deposition

Thermal evaporator: LADD Research filament evaporator

Physical vapor deposition (PVD): Denton Vacuum Explorer 14

Molecular vapor deposition (MVD): Applied MST

Deep Silicon Etcher

Inductively coupled plasma etcher (ICP): BMR Technology HiEtch ICP-etcher module

Characterization

Microscope

Scanning electron microscope (SEM): Quanta FEG 450 (High Vac, Low Vac, ESEM modes)

Probe station: Semiprobe Semiconductor characterization system: Keithley 4200

MDL Equipment Overview

Safety

The MDL management has implemented all reasonable measures to ensure that this cleanroom provides a safe and clean working environment. It is the responsibility of all users, guests and staff to act in a professional, courteous, and safe manner at all times while in the facility. Users violating the operating and safety rules of the facility or endangering the safety of them or other users will be denied further access to the laboratory at the sole discretion of the management.

Manuals

All manuals are available from the network drive \\storage02\medist$\MDL Manuals.

Hit Windows+R

Type \\storage02\medist$

Login using your campus Domain credential

CAMPUS\YOURUSERNAME

YOUR PASSWORD

MVD from Applied Microstructures

PVD from Denton Vacuum

XeF Etcher from Xactix

Nanoimprintor from Nanonex

SEM from FEI

DRIE and ICP from BMRTek

People

Name | Research Topic |

|---|---|

Abdus Salam Sarkar | 2D materials |

Chao Sui | Tissue/organ-on-chip and immunotherapy |

Elham Easy | Study of microstructure of additive manufacturing devices |

Greg Hader | Nano-sheet resonators |

Hearsh Hoshing | |

Hibal Ahmad | Thermal conductivity |

Javid Akhavan Taheri Boroujeni | 3D printing |

Jeric Hernandez | 2D material for thermoelectric measurement |

Jongyoun Son | ME Lab manager |

Ke Xu | |

Licheng Xiao | |

Kyungnam Kang | MDL manager |

Mengqi Fang | 2D material growth |

Na Liu | 2D material optical property measurement |

Seyed S Mohajerani | |

Seyed Mohammad Hosseini | 3D printing |

Shuai Yu | pHEMA hydrogel fabrication |

Siwei Chen | MTJ fabrication |

Yazhou Zhou | |

Yingtao Wang | Graphene device |

Youmna Mahmoud | 3D printing |

Yunong Tang | 2D materials fabrication |

Zheqi Li | Carbon nanotubes |

Zitao Tang | Graphene ring |

User Fees

Equipment | Hourly fee $ for Stevens Users (1 hour minimum) | Hourly fee $ for External Users | Note |

|---|---|---|---|

Mask aligner (MA6) | 50 | 100 | |

PVD | 50 (excluding pumping time) | 100 (excluding pumping time) | user brings crucibles/targets |

DRIE | 100 | 200 | |

ICP etcher | 100 | 200 | |

XeF2 etcher | 50 | 100 | |

Nanoimprintor | 50 | 100 | user brings mold photoresists |

Probe station | 50 | 100 | |

O2 Plasma | 50 | 100 | |

Spin coater, oven, hot plates, hood | 50 (exempted if using with MA6 or etchers) | 100 (exempted if using with MA6 or etchers) | user brings photoresists/developers |

SEM | 50 | 100 | |

AFM | 50 | 100 | user brings AFM tips |

Equipment training | 200 | 300 | |

Equipment operated by staff | 100 + equipment hourly fee | 100 + equipment hourly fee |